At Hartzell Air Movement, we recognize the critical role that fan design plays in achieving optimal performance and efficiency in air movement systems. Our expertise lies in crafting well-designed industrial fans that significantly impact airflow, pressure, energy consumption, noise levels, vibration, and overall reliability.

One area where Hartzell excels is in the design of fiberglass fans, featuring our unique one-piece composite wheel design. The solid construction of our one-piece composite wheels offers numerous advantages, including maximum corrosion resistance for reliable operation even in corrosive environments.

The one-piece composite wheel design contributes to enhanced aerodynamic performance. Our engineers meticulously engineered the airfoil shape of the wheel blades, to optimize airflow while minimizing turbulence. This results in improved efficiency and reduced energy consumption, ensuring that our fans operate at peak performance while saving energy costs.

Not only do our fiberglass fans provide superior performance, but they also simplify maintenance and reduce the risk of component failure. The one-piece design eliminates the need for complex maintenance procedures, ensuring hassle-free operation and longevity.

We are dedicated to innovation and delivering high-quality solutions. Our fiberglass fans with the unique one-piece composite wheel design are a testament to our commitment to excellence. We continuously strive to develop advanced industrial fan designs that provide superior performance, energy efficiency, and long-lasting durability. With Hartzell's fiberglass fans, customers can trust that they have reliable and efficient air movement solutions tailored to their specific requirements.

Understanding Fan Wheel Design

The fan wheel plays an important part in air movement systems. We understand that the fan wheel's design directly impacts the entire system's performance and efficiency. Factors such as blade shape, profile, angle, curvature, and material selection are crucial in achieving optimal airflow and minimizing resistance.

When it comes to designing fan wheels for fiberglass fans, unique challenges arise. Fiberglass fan applications require fan wheels that are not only efficient but also corrosion-resistant. Hartzell specializes in creating innovative fan wheel designs that meet these demands and deliver exceptional performance, efficiency, and durability for fiberglass fan applications.

With our expertise and knowledge in fan wheel design, we ensure that each fiberglass fan wheel is meticulously engineered to optimize airflow, minimize resistance, and deliver superior air movement. Our fan wheels are designed to meet the specific requirements of fiberglass fan applications, offering maximum performance and efficiency.

Hartzell's One-Piece Wheel Design

We are proud to offer our innovative one-piece composite wheel design for fiberglass fans, which provides significant advantages over traditional designs. Our unique construction eliminates joints prone to fatigue and failure, enhancing durability and reliability. This robust design ensures long-lasting performance, even in the most demanding environments.

The streamlined construction and optimized blade shape of our one-piece wheel design greatly improve aerodynamics and efficiency. Our fans deliver exceptional performance by facilitating smoother airflow, resulting in cost savings and reduced energy consumption. Our fiberglass fans, featuring the one-piece wheel design, are meticulously engineered to maximize airflow efficiency, providing outstanding air movement while minimizing energy requirements.

Additionally, the one-piece design reduces maintenance and minimizes downtime. With no regular inspections or adjustments required, maintenance needs are significantly reduced. The elimination of imbalanced wheels reduces vibration and wear, extending the lifespan of the fans. Customers benefit from enhanced durability, improved aerodynamics, increased energy efficiency, and reduced maintenance costs by choosing Hartzell's fiberglass fans with the one-piece wheel design.

The Science Behind the Design

There are numerous benefits to utilizing composites in fiberglass fan construction. Through our extensive expertise in material selection, we have chosen high-grade vinyl ester resin for our fiberglass fan wheels.

Using vinyl ester resin ensures exceptional corrosion resistance, guaranteeing that our fans have a prolonged lifespan and require minimal maintenance, even in the harshest environments. Our optimized blade shape and angle maximize aerodynamics, allowing us to generate the desired airflow with minimal energy consumption and low noise levels.

Our efficient airfoil designs enhance overall performance by reducing turbulence and maximizing efficiency. We eliminate imbalances through meticulous precision balancing techniques, leading to an extended fan lifespan and reduced vibrations. Moreover, we have incorporated additional design features that effectively minimize noise and vibration while maintaining efficient airflow.

Performance and Efficiency

We prioritize energy efficiency and cost savings in our fan designs. The one-piece wheel design is engineered to reduce air resistance and pressure losses, resulting in lower energy consumption and operational costs. We aim to provide customers with energy-efficient solutions that optimize airflow and pressure while minimizing their environmental impact.

To ensure the performance and reliability of our fans, we conduct rigorous testing and seek certifications from reputable organizations. Our comprehensive tests evaluate various factors, including airflow, pressure, efficiency, noise levels, and durability. These tests guarantee that our fans meet or exceed industry standards and performance requirements.

Certifications from renowned organizations like the Air Movement and Control Association (AMCA) further validate the performance claims of our fans and ensure adherence to established standards for airflow, efficiency, and noise levels. Our commitment to thorough testing and certifications demonstrates that our customers can have complete confidence in the performance and reliability of our air movement solutions.

With our advanced one-piece composite wheel design, emphasis on energy efficiency, and validation through comprehensive testing and certifications, we showcase our unwavering dedication to delivering high-quality, dependable air movement solutions.

Applications and Industries

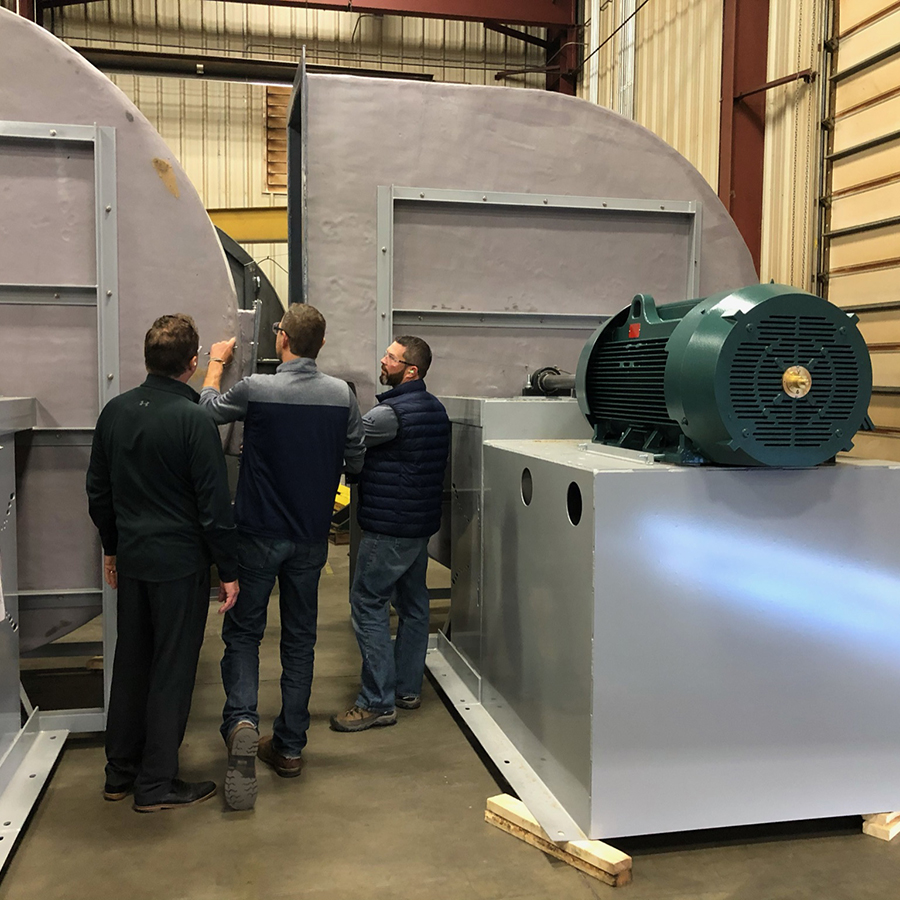

The impact of our one-piece wheel design extends across a wide range of industries, delivering exceptional performance and efficiency in air movement applications.

Our composite wheel construction excels in corrosive environments, providing outstanding corrosion resistance. Industries such as chemical processing, wastewater treatment, and marine applications greatly benefit from the durability and reliability of our one-piece design. With no joints or connections susceptible to corrosion, our fans ensure long-term performance and reliability in demanding environments.

We have an extensive track record of success, supported by numerous case studies showcasing the performance of our one-piece composite wheel design in various industries. Our fans have consistently delivered efficient air movement solutions, improved airflow, and achieved energy savings across sectors including manufacturing, mining, agriculture, and more. For instance, in a manufacturing plant, our one-piece composite wheel design enhanced ventilation efficiency, resulting in improved air quality, worker comfort, and increased productivity.

Through our commitment to delivering reliable and efficient air movement solutions, we have established ourselves as a trusted partner in multiple industries. Customers rely on our expertise and the proven performance of our one-piece composite wheel design to meet their specific air movement requirements and achieve optimal results.

Conclusion

At Hartzell Air Movement, we take great pride in the advantages and scientific principles behind our innovative one-piece composite wheel design in fiberglass fans. This exceptional design encompasses a range of benefits that ensure optimal performance, durability, and efficiency.

The hallmark of our one-piece composite wheel design is eliminating joints or connections in the fan wheel. This seamless construction minimizes airflow turbulence and pressure losses, improving overall performance and efficiency. Additionally, the absence of joints enhances the durability of our fans by eliminating potential weak points that could experience wear or damage over time.

The use of fiberglass in our fan construction further augments the durability and longevity of our products. Fiberglass is renowned for its exceptional corrosion resistance, rendering our fans suitable for various environments, including those with high humidity, chemical exposure, or corrosive gases. With our one-piece composite wheel design and fiberglass construction, our fans are engineered to withstand the most demanding conditions and provide reliable performance throughout their extended service life.

Furthermore, our one-piece composite wheel design incorporates aerodynamic principles to optimize airflow. Our team meticulously analyzes blade shape, angle, and airfoil design to ensure efficient airflow and minimal energy consumption. Maximizing airflow efficiency allows our fans to deliver the desired air movement while reducing operational costs and energy consumption.

We invite readers to explore our comprehensive range of fiberglass fans featuring the unique one-piece wheel design. Our fans offer superior performance, durability, and efficiency, underpinned by our unwavering commitment to innovation and quality. Discover how our one-piece wheel design can optimize your air movement needs and provide long-lasting, efficient solutions.

KEEP READING

See all posts

Greasing Fan Bearings: Tips & Insights by Hartzell Air Movement

"Mastering Fan Maintenance: Lubrication Essentials & Expert Insights"

The Science Behind Hartzell’s Unique One-Piece Wheel Design in Fiberglass Fans

Revolutionizing Air Movement: Hartzell's One-Piece Composite Wheel Design